Researchers from Waseda University in Japan have developed a new adaptive vascular stent that can automatically deploy at body temperature using 4D printing and a shape memory polymer composite. The stent is made from a polycaprolactone based material whose thermal transition temperature is precisely tuned so that it expands naturally at approximately 37 degrees Celsius once placed inside the body. This eliminates the need for external heating systems and reduces the complexity and invasiveness of conventional stent deployment procedures.

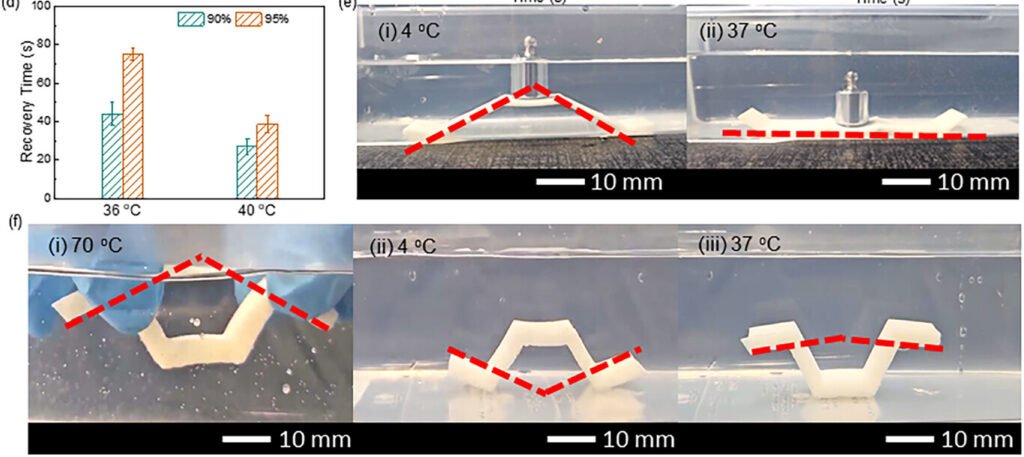

The team used projection micro stereolithography to fabricate micro architected coronary stents with fine structural control. By incorporating diethyl phthalate as a plasticizer, they adjusted the material’s behavior to achieve rapid shape recovery under physiological conditions. Mechanical testing and finite element simulations showed that the stents provide a balance of radial strength, flexibility, and biomechanical compliance, which are essential for supporting blood vessels without causing irritation or long term damage.

In vitro studies demonstrated strong cytocompatibility with human umbilical cells, and in vivo experiments in mice confirmed that the stents can safely expand and maintain structural integrity. The researchers emphasize that the programmable architecture of the stents allows for patient specific customization, which is important for treating complex vascular anatomies where standard stents may not fit well.

The work presents a generalizable strategy for designing next generation vascular implants that respond directly to the body’s natural environment. The researchers note that the same principles could be applied to other implantable devices that benefit from temperature activated deployment. The study highlights the potential for minimally invasive cardiovascular treatments that reduce procedural burden for both patients and clinicians while improving adaptability and safety.

Article from Waseda University: Low-Temperature-Activated Deployment of Smart 4D-Printed Vascular Stents

Abstract in Advanced Functional Materials: Adaptive 4D-Printed Vascular Stents With Low-Temperature-Activated and Intelligent Deployment