Researchers at the Institute of Industrial Science at the University of Tokyo have developed a new 3D‑printed backing system that significantly improves the performance of microneedle array patches used for vaccine delivery. The work responds to challenges highlighted during the COVID‑19 pandemic, particularly the need for vaccine formats that are easy to distribute, stable at room temperature, and simple to administer without trained medical personnel. Microneedle patches already offer advantages such as painless application and self‑administration, but their effectiveness can be limited when delivering live virus vaccines because the fabrication process can reduce viral viability and prevent the full dose from entering the skin.

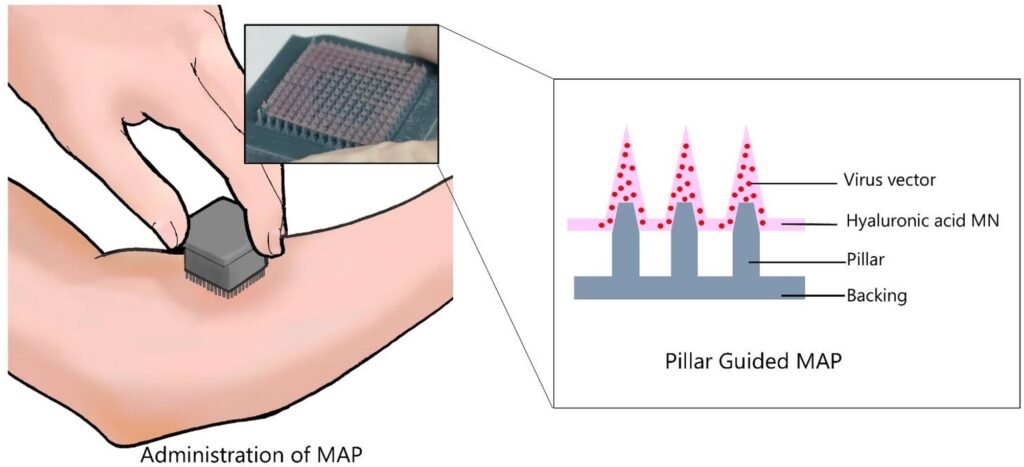

The research team addressed this by designing a 3D‑printed backing layer composed of small plastic pillars that fit into the microneedle mold before the viral solution is added. As the solution dries, dissolvable microneedles form at the tips of these pillars, ensuring that the live virus is concentrated at the point of delivery. This structure also shortens the drying time, which helps preserve more of the live virus during fabrication. According to the researchers, the pillar‑guided design functions similarly to inserting sticks into a popsicle mold, with the pillars serving as supports that shape and stabilize the microneedles.

To evaluate the system, the team compared the new pillar‑guided microneedle patches with conventional versions. They measured how much live virus remained after fabrication and then tested the patches in mice to assess immune response. The pillar‑guided patches retained more viable virus and produced stronger protective immunity against lethal SARS‑CoV‑2 challenge. These results indicate that the 3D‑printed backing layer improves both the stability of the vaccine during manufacturing and the effectiveness of delivery once applied to the skin.

The researchers emphasize that microneedle patches are particularly valuable for global vaccination efforts because they do not require refrigeration and can be administered without needles or syringes. The improved design could make live‑virus vaccines more accessible in regions with limited medical infrastructure.

By refining the structure of microneedle patches to preserve live virus and improve delivery efficiency, the team has introduced a practical advancement that could support rapid, large‑scale immunization during future outbreaks and expand the reach of vaccines in low‑resource settings.

Article from the University of Tokyo: A 3D-printed delivery system enhances vaccine delivery via microneedle array patch

Abstract in Scientific Reports: Precision dosing of recombinant vaccinia vaccine via pillar-guided microneedle patch confers SARS-CoV-2 immunity