Researchers from Sungkyunkwan University have developed a handheld surgical device that allows doctors to 3D print bone grafts directly onto fractures during operations. This in situ printing system eliminates the need for preoperative imaging, modeling, or prefabricated implants, making bone repair faster and more adaptable.

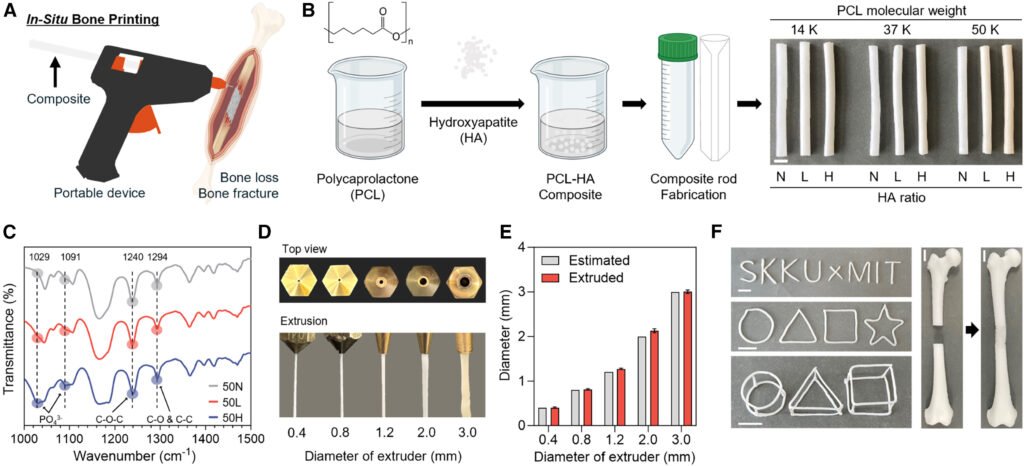

The device uses a filament made from hydroxyapatite, a mineral found in natural bone, and polycaprolactone, a biocompatible thermoplastic that melts at low temperatures. This combination allows the material to conform to irregular bone surfaces without harming surrounding tissue. Surgeons can adjust the ratio of these components to match the stiffness and strength needed for different anatomical sites.

Compact and manually operated, the device gives surgeons control over the direction, angle, and depth of printing. Bone grafts can be created in minutes, reducing surgical time and improving efficiency. The printed scaffolds are designed to degrade gradually and be replaced by natural bone, supporting long-term healing.

To reduce infection risk, the researchers embedded antibiotics such as vancomycin and gentamicin into the filament. These drugs are released slowly over several weeks at the surgical site, helping prevent postoperative infections while minimizing systemic side effects.

In animal trials using rabbits with severe femoral fractures, the printed grafts showed no signs of infection or tissue damage. The treated bones demonstrated better regeneration and improved structural properties compared to conventional bone cement. Measurements showed increases in bone surface area, cortical thickness, and mechanical strength.

The research team plans to refine the antibacterial properties of the material and prepare for human trials. They aim to standardize manufacturing and sterilization protocols and conduct further studies in larger animal models to meet regulatory requirements.