Researchers at Seoul National University of Science and Technology (SEOULTECH) have developed a groundbreaking tactile sensing platform using 3D-printed auxetic mechanical metamaterials (AMMs), which could significantly enhance the performance of wearable pressure sensors. Auxetic materials are known for their unusual property of contracting inward when compressed, allowing them to concentrate strain in specific regions. This behavior makes them ideal for tactile sensing applications in robotics, prosthetics, and health monitoring, but traditional designs have faced limitations in fabrication and adaptability.

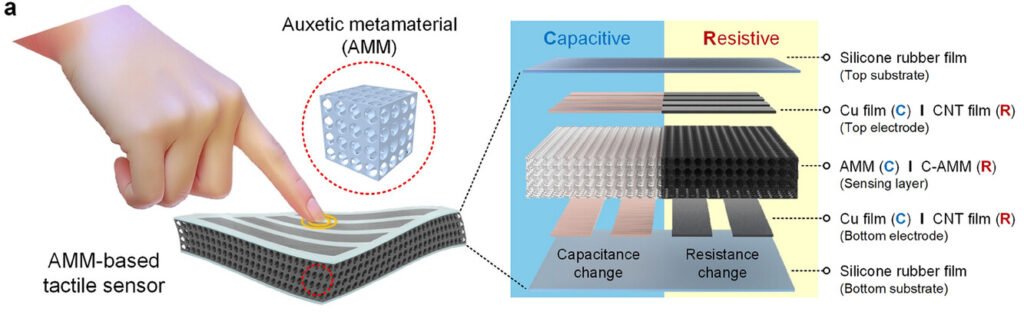

To overcome these challenges, the SEOULTECH team used digital light processing (DLP) 3D printing to create a cubic lattice structure embedded with spherical voids. This design allows precise control over the sensor’s geometry without altering the base material, enabling consistent performance across different configurations. The resulting platform supports both capacitive and piezoresistive sensing modes, making it highly versatile. In capacitive mode, pressure changes the spacing between electrodes and the distribution of the dielectric material. In piezoresistive mode, a carbon nanotube coating alters its resistance in response to mechanical stress.

Unlike conventional porous sensors, the auxetic structure resists lateral expansion, which minimizes interference and improves wearability. The researchers demonstrated the technology in two proof-of-concept applications: a tactile array capable of spatial pressure mapping and object classification, and a smart insole system that monitors gait and detects pronation types. Both systems showed high sensitivity, low crosstalk between sensing units, and stable performance even when embedded in confined environments.