Researchers at Kyushu University have developed a novel 3D bioprinting method to create customized meals for people with dysphagia—a condition that makes swallowing difficult and affects millions globally, especially in aging populations like Japan. Their innovation could dramatically improve both the safety and enjoyment of eating for individuals who currently rely on texture-modified foods like purées and jellies.

The team’s approach centers on a specially formulated bioink made from a stable oil-in-water emulsion combined with egg white proteins, stabilizers, and magnesium chloride. This mixture is designed to respond to controlled bursts of radiofrequency (RF) or microwave (MW) energy, which selectively heat the bioink and trigger protein denaturation—transforming the liquid into a gel with adjustable texture.

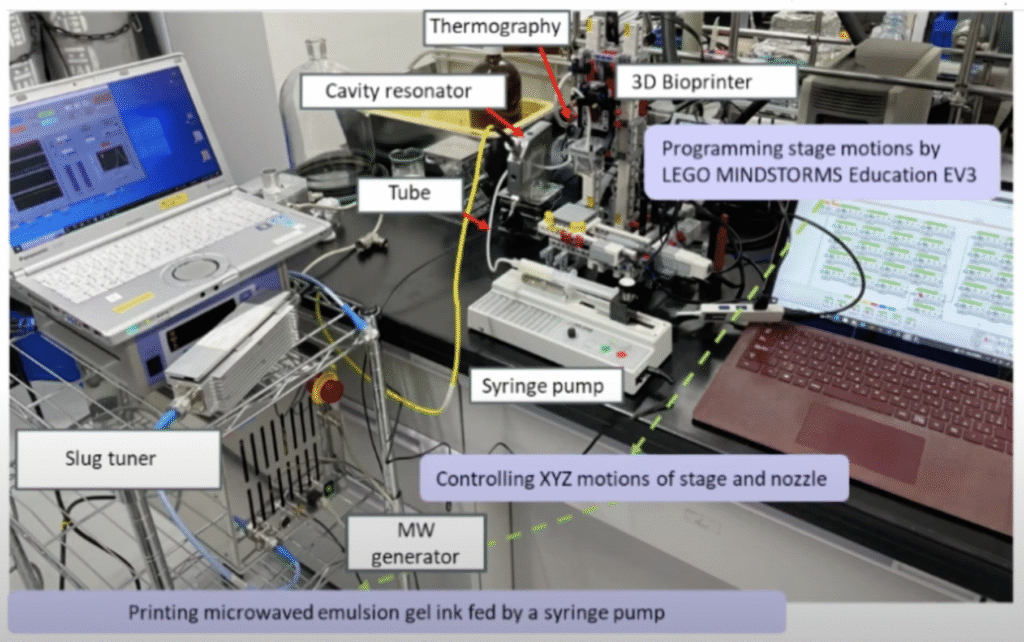

Using a custom-built 3D bioprinter powered by Lego Mindstorms EV3, the researchers extrude the bioink through a thin applicator while applying RF or MW energy. This allows them to print layer-by-layer food structures with precise control over texture, adhesiveness, and water retention. By simply changing the frequency of the energy applied, they can tailor the final product to meet individual dietary needs. For example: Lower frequencies (200 MHz, RF range) produce firmer gels with better water retention, while higher frequencies (2.45 GHz, typical of household microwaves) yield softer, more adhesive gels.

This frequency-based control allows for personalized dysphagia diets that match the swallowing capabilities of each patient—offering a safer and more dignified alternative to one-size-fits-all purées. Associate Professor Shuntaro Tsubaki, the study’s lead author, emphasized the importance of making meals not just safe but also appealing: “Our goal is to create meals that are not only safe but also enjoyable.”

Here’s a video from Kyushu University that explains more:

Article from Kyushu University: Crafting the future of dysphagia diets with 3D printing

Abstract in Scientific Reports: Radiofrequency and microwave 3D bioprinting of emulsion gel for dysphagia diets